Machine Shop Services & Materials

Services

Engineering Assistance

Finishing

Cleaning & Deburring

Honing

High Precision & Finish

Lapping

CNC

Milling & Turning

Manual

Milling & Turning

Screw Machines

Turning

Sawing

Material Preparation

Sulfur-free cutting fluids

To meet the needs of many of our customers with special applications, we use only sulphur-free cutting fluids.

Materials We Machine

Aluminum Alloys

All Types (6061 -T6, 7075 Etc.)

Composites

Iron Epoxy, Kevlar, Noryl, Etc.

Controlled Expansion Alloy

Kovar, Nickel 200 --Nickel 270 etc.

Copper Alloys

All Copper Alloys (Beryllium Copper / Be-Cu)

Nickel Alloys

Nickel 200, Monel, Cu-Ni 715

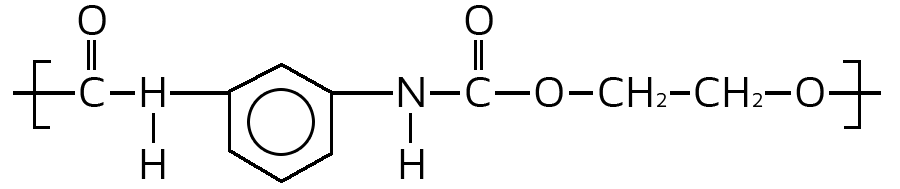

Plastics & Polymers

Polycarbonate, Nylon, Teflon, Polyimide (Vespel®), Polysulfone, Lexan Ardel, Delrin, Acrylic, PVC, TPX DX845

Specialty Alloys

All Types (Electronic Iron, Consumet Core Iron, Vacuum Melt Core Iron)

Steels

All

Polyimide machining (Vespel®) specialists

Minimatics is your high-quality and reliable close-tolerance, precision machine shop in Silicon Valley.

Minimatics has extensive experience serving customers in the aerospace, medical, and telecommunications industries. Utilizing customer relationships spanning decades, Minimatics understands the demands of each industry and how to produce the work necessary to that meet their exacting standards.

Minimatics currently possesses a variety of CNC machine shop services to meet your manufacturing requirements, including prototype development, engineering assistance, tight tolerance CNC turning and milling, precision honing, manual machining, lapping, deburring/finishing, and cleaning.

While anyone can purchase equipment, and call themselves a machine shop, what distinguishes Minimatics from competing machine shops are our people and our culture. Our production floor team has an average tenure of 15 years; they are journeymen craftsmen in their respective fields. Their skill matched with the correct equipment for the job allows us to accurately machine complex parts and prototypes with little waste thus reducing costs and turnaround time.

We are well-versed in handling difficult-to-machine materials and challenging jobs that other machine shops prefer to avoid, so please contact us with any questions, and we’ll be happy to help.

Aerospace Machining

Extensive Experience

Minimatics was established in 1961 on the San Francisco Peninsula, and from our earliest days, we have provided custom precision machined parts to the aerospace community. In the late 1950s, the San Francisco Bay Area's Aerospace Industries' need for small parts machining expanded significantly due to the NASA AMES Research R&D facilities adjacent to Moffett Naval Airfield and other Aerospace firms expanding into the surrounding area, which is now known as Silicon Valley.

In the subsequent 50+ years, the dramatic transformation of the San Francisco Peninsula into a worldwide center of innovation - Silicon Valley - has driven Minimatics to build the capabilities and expertise necessary to satisfy small parts manufacturing for high-tech startups and Fortune 500 companies. Minimatics is an *ITAR registered machine shop possessing the requisite aerospace machining skill and experience to meet the most advanced needs of industry leaders.

Machine Shop Services

Minimatics delivers custom precision machined aerospace parts on time, which meet the exacting standards of this highly technical industry.

Our production facility features state-of-the-art precision CNC milling and turning equipment and dedicated honing, lapping, and deburring departments that allow us to machine tight tolerances that are 1/30 of a human hair (.00005).

While anyone can purchase equipment and call themselves a machine shop, what distinguishes Minimatics from competing high-tech machine shops are our people and our culture. Our production floor team has an average tenure of 15 years; they are journeymen craftsmen in their respective fields. Our skills matched with the correct equipment for the job allows us to accurately machine complex aerospace parts and prototypes with little waste, thus reducing costs and turnaround time.

Material Specialties

At Minimatics, we meet the unique requests of companies involved in military and commercial aerospace manufacturing. We only use sulfur-free cutting fluids, and we specialize in precision machining exotic materials such as Invar, Kovar, Beryllium Copper, Cupronickel, Stainless all grades, Aluminum alloys, Polyimide (Vespel), Polymers, and more. Click here for a full list on the materials page.

Quality

As aerospace manufacturing in the 21st century becomes progressively more specialized and precise, Minimatics maintains an exceptional level of quality.

Our employees' longstanding commitment to our company allows them to embrace and nurture the culture of quality that defines Minimatics.

Minimatics is an ISO 9001:2015 certified company. Our manufacturing system adheres to ISO 9001:2015 standards and is re-certified by independent auditors annually.

Minimatics is an *ITAR registered machine shop

ITAR (The International Traffic in Arms Regulations) is a program administered by the U.S. State Department Directorate of Defense Trade Controls. A rigorous training and monitoring program ensures that we strictly conform to the State Department’s requirements.

Medical Prototypes & Production Parts

Silicon Valley medical

and biomedical firms rely on

Minimatics to machine parts with complex geometries and tight tolerances to their specifications. New products & technologies often require new approaches to small parts machining to more precise tolerances. We have extensive experience machining medical parts and working with medical prototypes.

Minimatics makes house calls

Call us -- discussions early in the project can save money and time. Your success is imperative to us. Minimatics will gladly assist your engineering staff in determining the machinability of your parts based on the materials and part configuration. Our goal is to make your parts as cost-effective and efficient to manufacture as practical. Our machining engineer has over 40 years of experience in the machining industry, with 10 years working directly with OEM medical companies.

Working closely with your engineers and R&D department is the basis of the manufacturing partnership that Minimatics builds with all its clients. We are happy to sign the required NDAs with your company.

Minimatics medical service

Fiber-Optics &

Communication Systems

Founded in 1961 on the San Francisco-Bay Area Peninsula, Minimatics has extensive experience producing components for the communications industry dating back to the early origins of radar. In our 50-plus years of operation, our high-precision machined parts can be found in communications systems ranging from fiber-optics to Doppler radar used in military and commercial products.

Regardless of your project's scope and size, Minimatics' performance will meet your industry's exacting standards on time and on budget. With a diverse customer base that spans startups to Fortune 500 corporations. Minimatics knows the unique material and quality standards required by telecommunications industry leaders. We specialize in precision small parts machining from low expansion alloys like Kovar, for metal to glass seals to commonly machined materials like stainless steels and copper alloys. Minimatics uses Sulfur Free cutting fluids to prevent contamination / "outgassing" in the final stages of part assembly.

Delivering an exceptional level of quality to our customers is paramount to Minimatics. Our manufacturing system conforms to ISO 9001:2015 standards and receives annual independent audits to re-certify its status. Minimatics is an ITAR-registered machine shop. Minimatics will comply with the ITAR process on all ITAR designated projects in accordance with the International Traffic in Arms Regulations (ITAR) administered by the U.S. State Department Directorate of Defense Trade Controls.